Sale

Shown with dovetailed aluminum jaw plates, included as standard equipment

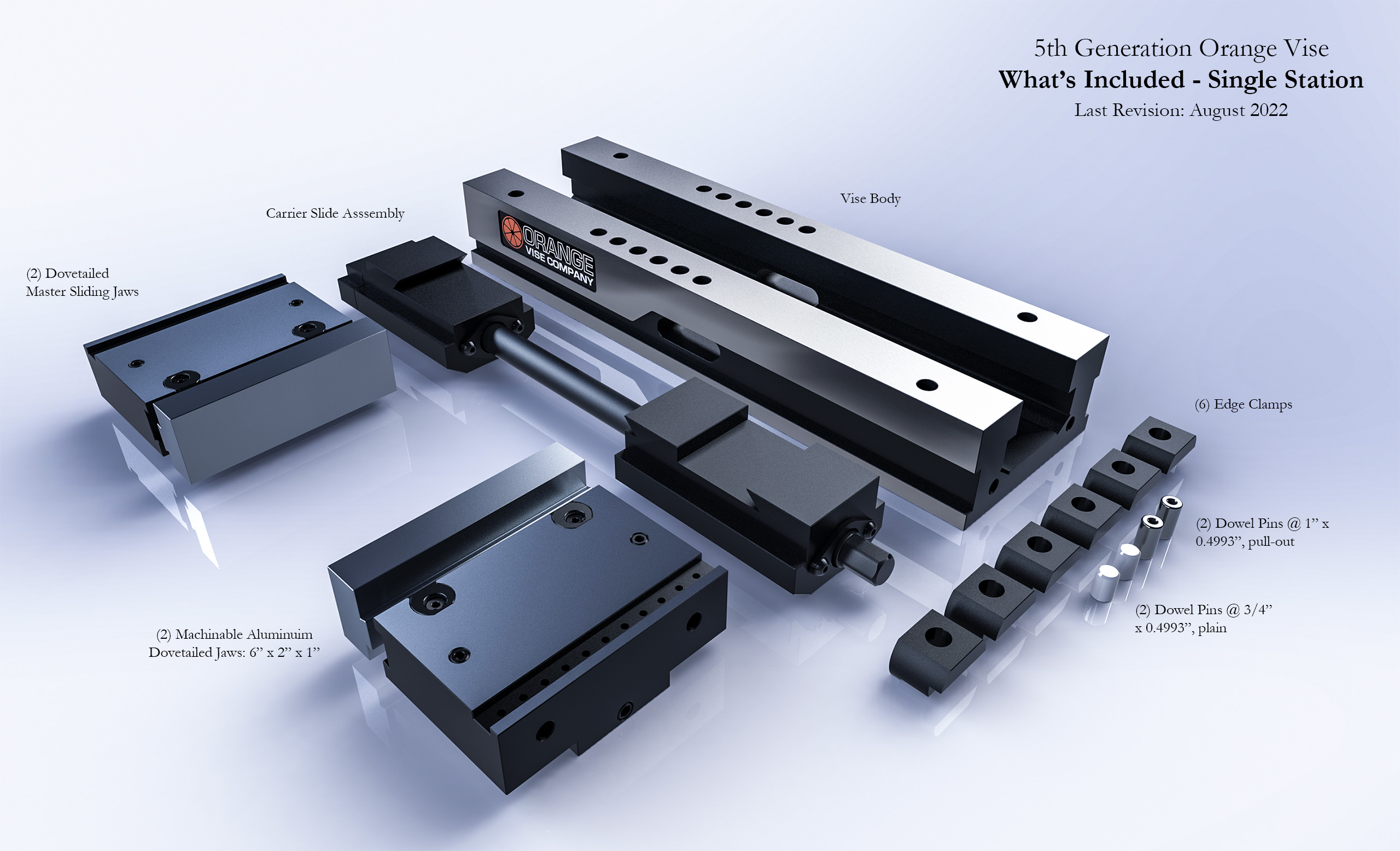

What's included with the 5th generation Orange single station vise

Shown with OPTIONAL hardened jaw plates, sold separately

Shown with optional aluminum jaw blocks, SKU# 701-002, sold invidivually

Orange Fourth-Generation CNC Machine Vises

Fourth-generation vise with a dovetailed jaw interface as standard equipment. Compatible with CarveSmart™ dovetailed quick-change jaws as well as 1/2"-13 bolt-on jaws in a 3.875" x 0.9375" bolt hole pattern.

The deluxe single-station vises are identical to our dual-station vises, but without center jaws. You may purchase any of our center jaws separately to convert deluxe single-station vises into dual-station vises. No additional hardware is necessary.

Materials

- Master sliding jaws and carriers are made of Dura-Bar® cast iron (black oxided).

- Vise bodies and master center jaws are also made of Dura-Bar cast iron.

- Hardened bolt-on jaws and narrow center jaws are made of steel.

Performance

- Clamping force ratio: 600 lbs per 10-ft lbs torque

- Max recommended clamping force: 7200 lbs (120 ft lbs torque)

- Linearly consistent force-to-torque across the entire range, highly repeatable over time

What's Included:

- Two (2) sliding jaws with dovetail jaw integration

- Two (2) machinable aluminum dovetailed quick-change jaw plates

- Six (6) edge clamps (T-slot nuts and 1/2" or M12 hardware not included)

- Four (4) dowel pins, 0.4993" OD

Minimum Closing Gaps

Due to the sealed nature of the OV6 vise carrier design, the minimum closing gap of the vise varies among models.

- The 16", 17.5", 20", and 22" vises close completely in dual station configuration.

- The 16", 17.5", and 20" vises close completely in single station configuration with dovetailed jaws installed. They will leave a gap with the dovetailed jaws removed.

- The 22" vise will leave a 2.5" gap in single station configuration even with dovetailed jaws installed. If you need to clamp on smaller material, use the vise in dual station configuration but leave one station empty, or clamp a dummy part in the unused station.

- The 26" vise will leave a 6.5" gap in single station configuration and up to a 4" gap in dual station configuration. When clamping small parts in single station configuration, clamp a sufficiently large dummy part in the unused station.

- The 26" vise is not designed to clamp small parts in dual station configuration. However, this can be accomplished by separately purchasing a 20" carrier assembly (not included).

Vise Handles

Vises do not include handles. We recommend using a torque wrench or an electric impact wrench with a 3/4" hex, 6 point, deep impact socket.